PTFE Baghouse Filter Bags are made from premium Polytetrafluoroethylene raw fibers used in industrial air filtration applications with severe chemical environments at high temperatures. These filter bags are highly resistant to acids, alkalis, hydrolysis, and oxidation. They have a high operating temperature range of 480°F (248°C), handling surges up to 550°F (287°C).

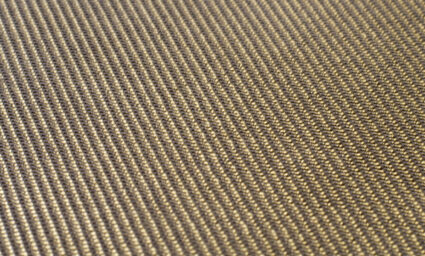

PTFE filter bags have a smooth surface, making them easy to clean during the pulsing cycle. During the pulsing cycle, the dust easily slides off the vertical filter bags. PTFE filter bags offer a longer service life and higher air permeability, helping to save energy costs and offset the higher initial investment on bag installation.

It is important to note that these PTFE baghouse filter bags are not PTFE membrane coated; however, adding a PFTE membrane will improve performance even more.