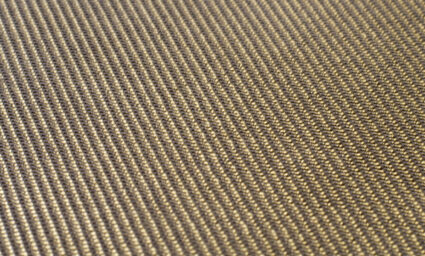

Polyphenylene Sulfide (PPS) baghouse filter bags are highly resistant to chemicals such as acids, alkaline, organic solvents, and corrosion in high-temperature environments. PPS filter bags are also flame and hydrolysis resistant. PPS baghouse filter bags are suited for high humidity and chemical attacks where emission standards are tight. It has good flame resistance, where continuous operating temperatures are up to 375°F (190°C) with surges up to 400°F (204°C). They are an extremely stable baghouse filter bag option for the power generation, cement, asphalt, and metals industry.