The aluminum extrusion industry is experiencing a surge in demand driven by growth in construction, transportation, and renewable energy sectors. Manufacturers are striving to meet higher quality standards while ensuring operational efficiency. One critical component in this process is the run out roller cover.

These covers play a pivotal role in maintaining the integrity of aluminum profiles during high-temperature extrusion, preventing surface damage, and ensuring smooth handling. However, many extruders unknowingly compromise on quality by using substandard roller covers, often falsely marketed as high-grade solutions. This article explores the risks of such choices and highlights Albarrie’s solutions for overcoming these challenges.

Conveyor roller covers act as a protective buffer, ensuring freshly extruded aluminum profiles remain undamaged during processing. This protection is essential as aluminum exits the press at temperatures of 750–930°F (400–500°C), making it vulnerable to marking, scratches, and deformation.

High-performance roller covers contribute to uninterrupted production, smooth handling, and consistent product quality. They are indispensable for maintaining operational efficiency in an industry where precision and reliability are paramount.

While generic roller covers may appear cost-effective, they often come with hidden expenses:

These issues stem from deceptive practices, where roller covers are marketed as high-performance but are composed of blended, recycled, or low-grade fibers rather than pure meta-aramid or para-aramid materials like Kevlar® or Nomex®.

Albarrie stands out as the only ISO-certified North American manufacturer of high-performance roller covers. Unlike competitors that rely on imported, unregulated materials, Albarrie maintains full control over its supply chain, sourcing premium virgin fibers and employing proprietary manufacturing techniques.

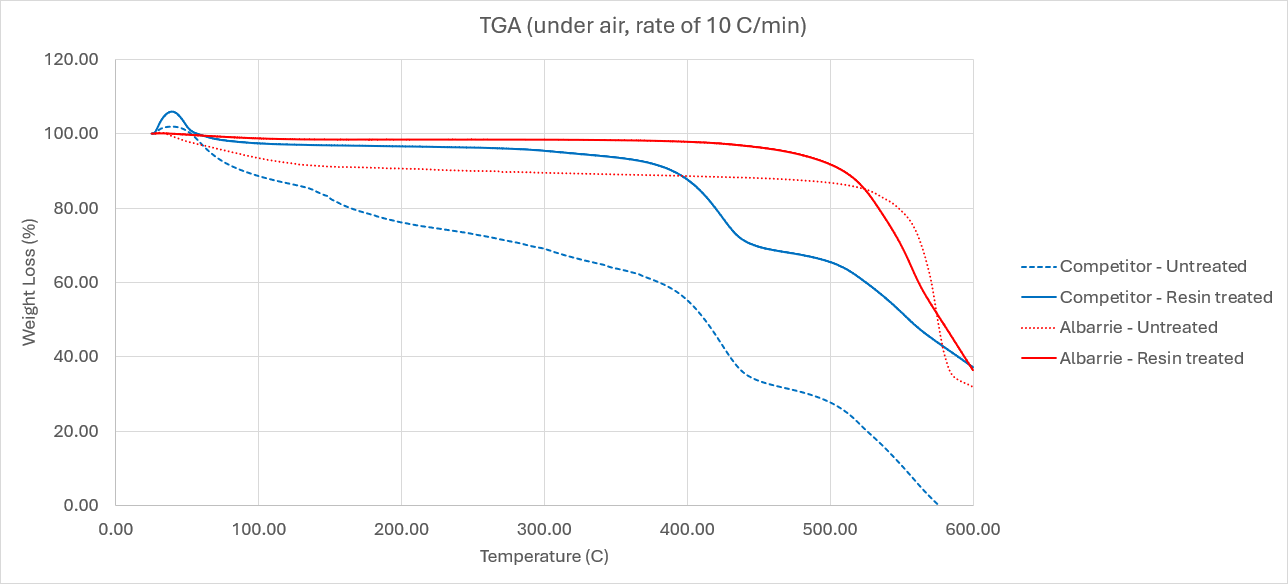

Albarrie’s Defender™ Series Roller Covers were tested against generic alternatives using Thermogravimetric Analysis. Results showed that Albarrie’s covers endured up to 932°F (500°C) without degradation, while competitors’ products began degrading as early as 392°F (200°C) and failed completely at 752°F (400°C). This resilience translates into fewer replacements, reduced downtime, and enhanced safety.

Albarrie offers two product lines to meet diverse customer needs:

Additional offerings include separator rollers, slat and beam covers, spacer bar sleeves, and heat-protective tape, ensuring comprehensive solutions for aluminum extrusion facilities.

Switching to Albarrie’s roller covers offers significant advantages:

For over 40 years, Albarrie has been a trusted partner in the aluminum extrusion industry, offering innovative solutions backed by industry expertise. By choosing Albarrie, you’re not just purchasing roller covers—you’re investing in operational excellence, safety, and long-term profitability.

Take the first step toward elevating your aluminum extrusion process. Contact Albarrie’s sales and technical team today for tailored solutions that set a new standard in the industry.