Airborne dust is generated by different sources in diverse industries like construction, mining, metalworking, foundry, food and beverage processing, pharmaceutical manufacturing, and more. This dust can range in size from large particles visible to the naked eye to smaller particles only visible under a microscope. By regulation, manufacturers must ensure environmental standards are met by reducing emissions through environmental equipment such as baghouses or dust collectors.

There are many features, parts, and scientific principles to understand when operating environmental equipment. First and foremost, understanding the basic principles of industrial air filtration and how it removes dust particles from demanding manufacturing processes is key to ensuring your dust collector or baghouse remains operational at a lower cost.

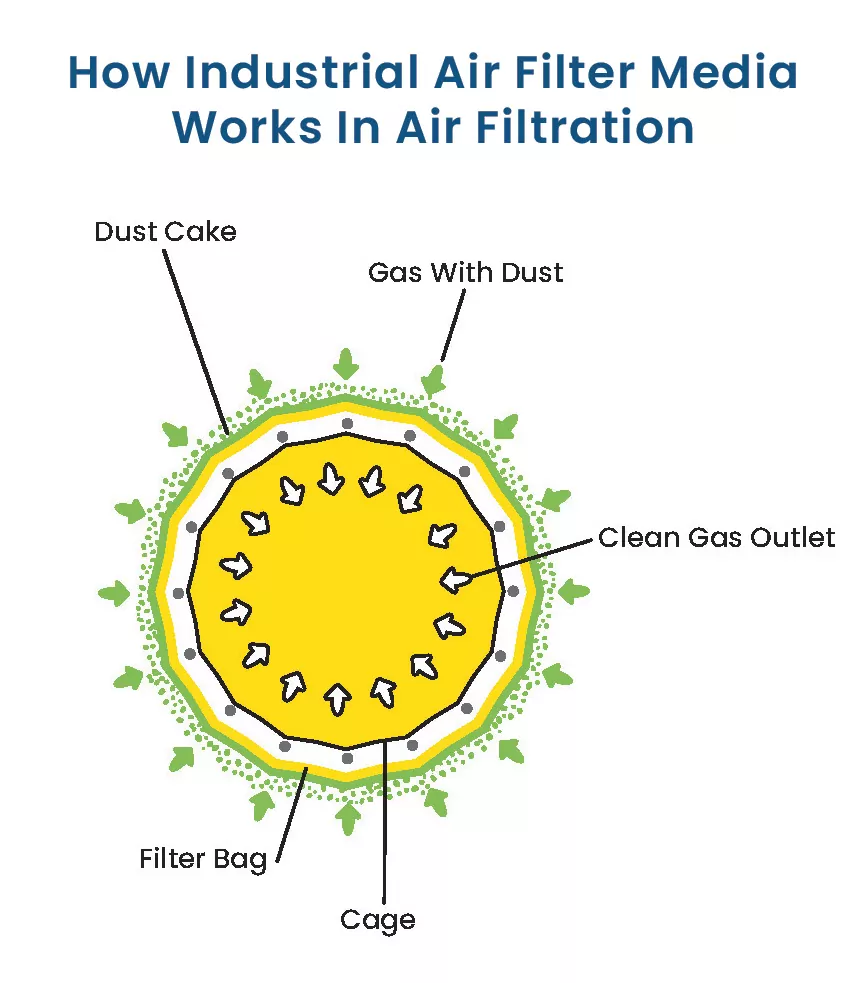

Industrial air filtration in baghouses physically captures dust particles on an industrial air filter media (typically fabric). It is important to note that industrial air filtration is a physical process, not a chemical one. This means the dust particles are not destroyed but collected on the air filter media or fabric.

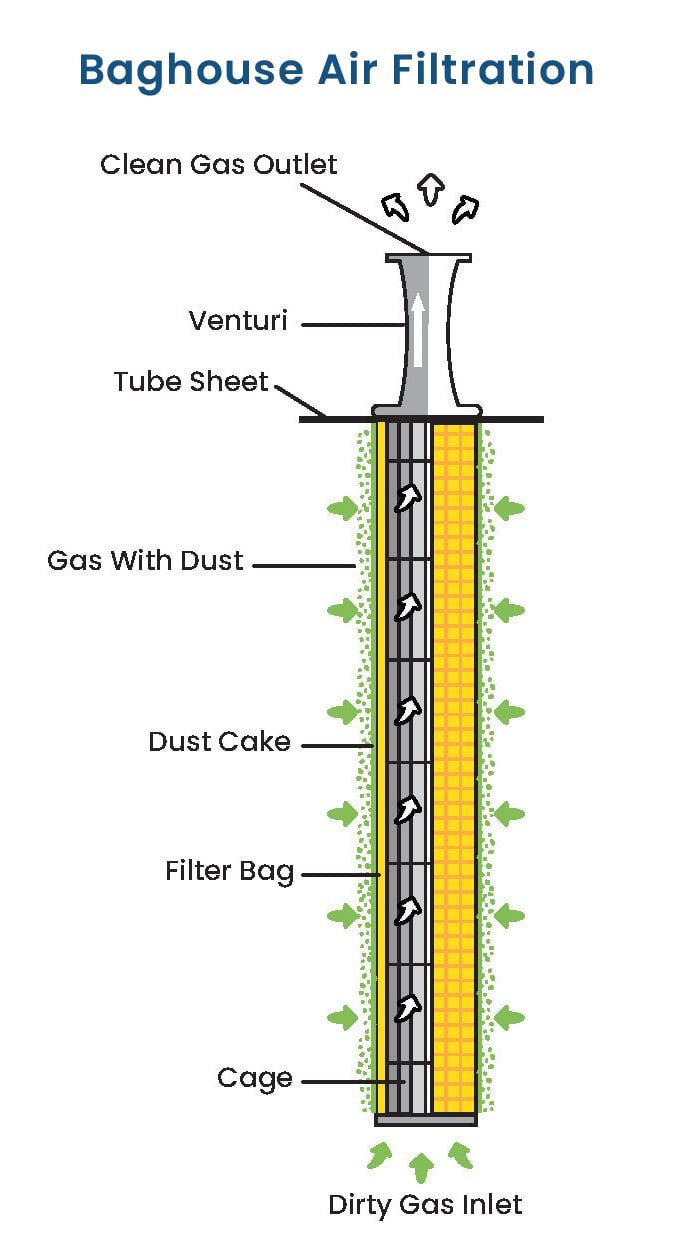

As dirty, dusty air enters the baghouse, it is pushed or pulled through a series of fabric filters called baghouse filter bags. Larger dust particles are typically removed by contact with an internal target plate. The turbulent air then rises, moving finer dust particles into the filter media where they are captured. The cleaned air passes through and up inside the air filter media to clean the air plenum before it’s exhausted into the atmosphere or back into the process. Finally, the captured dust is cleaned off the filter bags by blowing air through the bags, allowing the dust to drop down into a hopper for disposal.

There are four scientific principles that explain how industrial air filtration works with baghouse filter bags. These principles help buyers understand why fabrics perform better when cleaning the air.

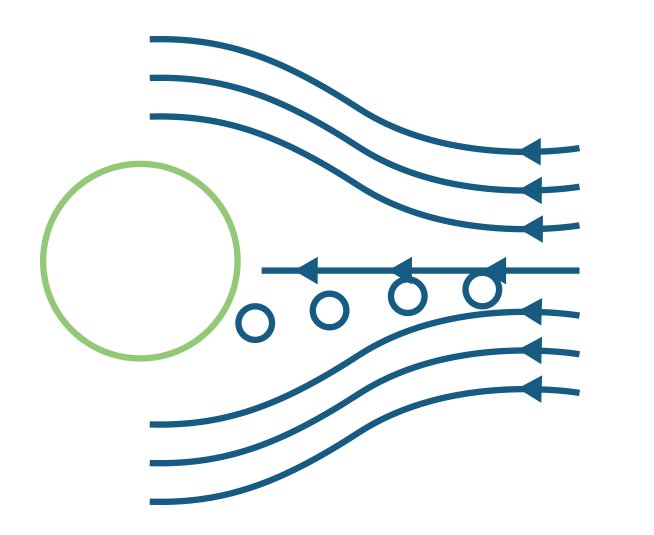

If the particles in the gas flow stream are larger than the pores or openings in the filter medium, then they will be removed because of the direct interception by the holes. The particles are physically trapped by the fibers and cannot pass through the filter.

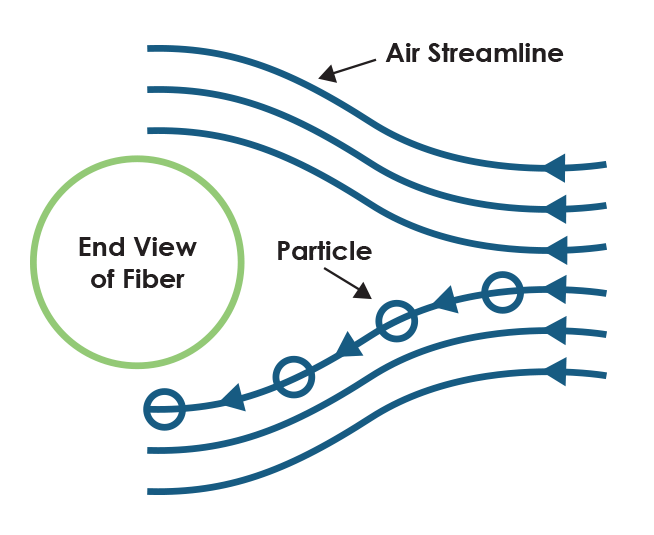

This occurs when particles collide with the fibers of the filter media at high speeds. The particles are then deflected or slowed down by the impact, and eventually become trapped by the fibers.

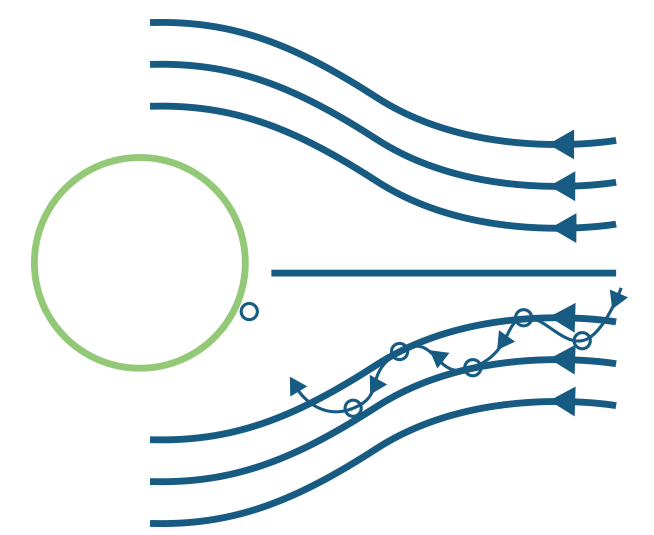

In this process, particles are on a collision course with flow stream molecules. These frequent collisions cause the suspended particles to move randomly around the flow lines. When particles diffuse or spread out as they move through the filter media, they come in contact with more fibers and are eventually trapped by the media.

This occurs when particles are too large to pass through the pores of the filter media. The particles are then physically trapped by the pores and cannot pass through the filter.

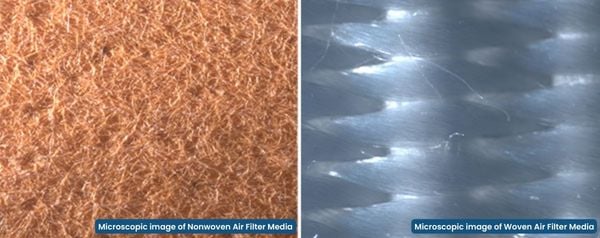

Choosing the right filter media is crucial to successful air filtration and reduced emissions. Manufacturers can choose between woven or nonwoven filter media depending on their baghouse OEM specifications and manufacturing processes. Nonwovens tend to perform better due to the weblike structure created during the manufacturing process. This weblike structure offers various pore sizes, or tiny holes, in which the dust particles pass through and attach to the fabric’s fiber while allowing the cleaned air to pass through the fabric. Nonwovens also have better performance properties like chemical and high-temperature resistance.

When purchasing baghouse filter bags, it’s essential to consider the total cost of ownership, amongst other deciding factors. The total cost of ownership goes beyond the initial purchase price. Manufacturers must consider installation and maintenance costs. The air filter medium chosen will affect things like utility consumption (electricity or compressed air), emissions, and potential downtime. Other things to consider include the operating conditions temperature, humidity, corrosiveness), the air-to-cloth ratio, and the dust’s physical characteristics (stickiness, abrasiveness, etc.). These will affect which filter media is best suited for your application.

Want to learn more about Industrial Air Filtration and Baghouse Operations, including troubleshooting tips and tricks to keep operations running smooth and efficient? Follow Albarrie on social media channels Facebook, LinkedIn, Twitter, and Instagram, and check back here as we share our 40+ years of experience and expertise.