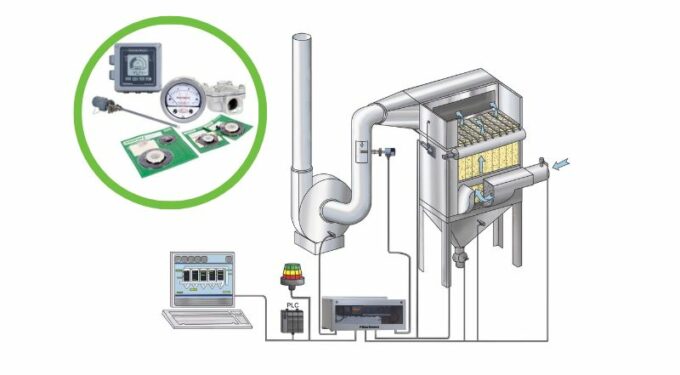

Maintaining and cleaning the baghouse and improving overall costs in air filtration is a frequent and painful activity for many producers. Optimizing baghouse processes begins with the equipment and the filter bags, but it doesn’t end there. Preventative maintenance is critical to ensure emissions-free operations. Get help by adding additional technologies to instantly measure air pressure and identify baghouse leaks, a failed solenoid, or a problematic diaphragm. Albarrie offers timer boards, pressure gauges, replacement solenoids, diaphragm valves, repair kits, and caps and hooks to assist producers in maintaining effective baghouse operations.