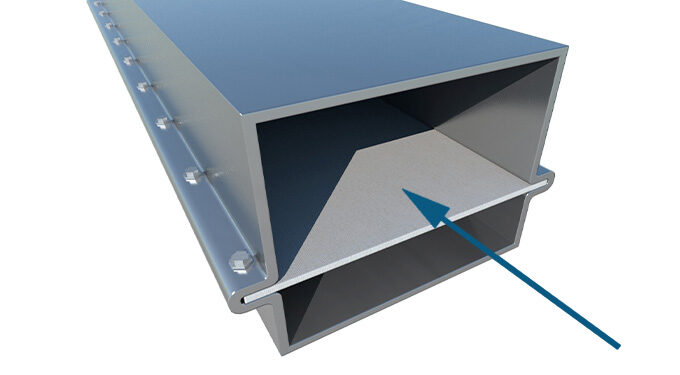

Airslide or air gravity conveyors ensure successful air conveyance of fine powders for transportation and storage. Using simple, natural technology (gravity and air), air gravity conveyors are a practical and economical solution to transporting and handling bulk powders. The conveyor system is installed along a path at various angles between a high and low point, allowing gravity to work. A fluidization cloth, or microporous fabric, is installed along the enclosed chamber’s centerline, creating a space above and below the material. A fan is attached to the system to provide airflow. The area above the fluidization cloth allows the powders to move. The space below the fluidization cloth acts as a low-pressure air chamber, pushing air up through the fabric and moving the powders in a fluid-like motion.

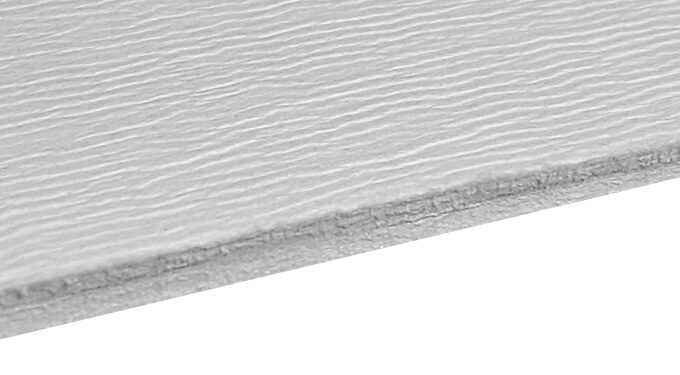

Albarrie’s AlSlide™ Fluidizing Fabric is specifically designed to fluidize bulk powders. It’s made from nonwoven technical fabrics with a woven scrim support. AlSlide™ provides uniform and consistent fluidization of conveyed dry powders in pneumatic systems. AlSlide™ will not allow particulates to infiltrate through its surface thanks to the fabric’s tiny and even pore openings, resulting in less physical abrasion. Its smooth surface provides no air leaks and improves airflow while preventing caking.