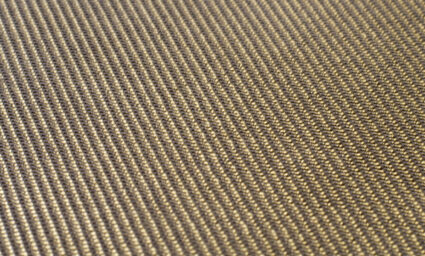

Meta-Aramid (Nomex®) baghouse filter bags are relied on by the asphalt industry (and others) due to its high temperature range and excellent chemical resistance. Meta-Aramid does not shrink in high-temperature environments where continuous operating temperatures are up to 400°F (204°C) with surges up to 430°F (221°C). The fiber also offers very good tensile strength and abrasion resistance. A high tensile strength means the fibers won’t break or fray in abrasive environments. This leads to good mechanical stability, which means the filter bag will maintain its shape. Meta Aramid can withstand high temperatures without melting.

Albarrie relies on Meta-Aramid, layered with a high-performing surface layer of Polyimide P84® fiber for enhanced filtration performance in one of our specialty baghouse filter bags – Tandem™ High Performance Filter Bags. The addition of a P84® top layer, with its multilobal fiber construction, to any product, immediately improves surface filtration due to its unique fabric properties. Polyimide P84® provides a higher surface area for effective surface filtration and dust cake formation. Polyimide P84® also helps maintain high airflow and low‐pressure drop across the media. Achieve up to 99.9% filtration efficiency in highly abrasive environments