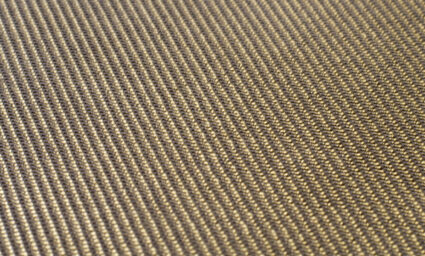

Para-Aramid (Kevlar®) is a robust and rigid fiber known for its exceptional resistance to abrasion and cutting. Para-aramid falls within the aromatic polyamide fiber category. Aromatic polyamides (APs) are high-performance materials with high levels of thermal and chemical stabilities, and mechanical resistance. Like its counterpart, meta-aramid, Kevlar® is a naturally flame-resistant, high-temperature fiber that will not melt in extreme conditions. Kevlar® has superior strength, is five times stronger than steel on an equal weight basis, yet it’s lightweight.

Nonwoven para-aramid technical textile is famous for its use in protective apparel because of its cut-resistant properties. Scientists and engineers have pushed the limits with Kevlar®, which has proven performance in many other applications like making boat hulls and kayaks, insulation for airplanes and spacecrafts, to reinforcements for automotive belts and batteries. Kevlar® is genuinely today’s super fiber

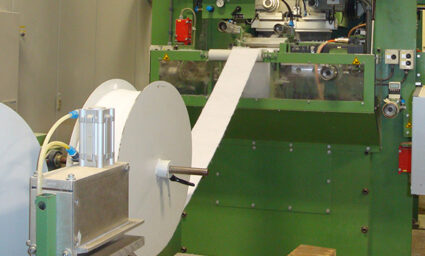

Albarrie relies on the strength, durability, high-temperature resistance and protective qualities of para-aramid to make its unique Defender Series Fullback Rollers, Separator Rollers, and Durafiber Boards for high-temperature conveyance and material handling applications. We use DuPont’s Kevlar® or generic fibers to manufacture para-aramid technical fabric in thicknesses between 0.0393 and 0.512 inches (1-13 mm) with weight ranges between 5.90 and 112.9 oz/yd² (200-3830 g/m²)