The modern world is increasingly noisy. From vehicle transportation to generators, heavy equipment, wind turbines, and more, the effects of noise on people and the environment are harmful. Scientists have linked human cardiovascular and mental disorders to elevated noise levels. In wildlife, scientists have found that our noisy world affects everything from animal reproduction to disorganizing their predator-prey instincts and communication ability. Noise disruption, in turn, affects our entire ecosystem.

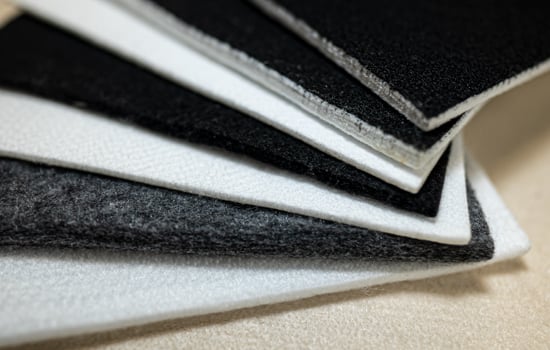

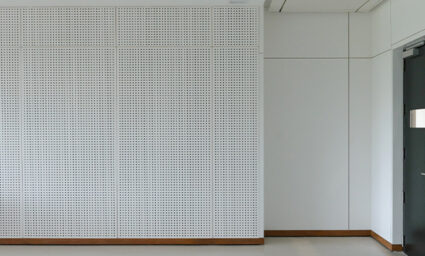

High noise levels have led regulators, planners, and engineers to implement laws, processes, and engineering controls to diminish overexposure to noise. These controls have also led to innovations in noise dampening and insulation products, requiring nonwoven technical textiles to help filter, diffuse, or absorb noise in buildings, vehicles, machinery, and equipment. Additionally, architectural sound insulation has become well-known for private home use and public buildings for their aesthetics and functional sound absorption properties. Some applications involve high temperatures and elevated vibrations, requiring fabrics that withstand heat while protecting people from the sound’s energy impacts.

Fabric performance is directly related to the chosen fiber properties and treatments. Polyester and PET offer excellent tensile strength and abrasion resistance but operate at lower temperatures. Polypropylene has good tensile strength but withstands higher temperatures and has excellent resistance to chemicals like acid and alkalis, which works better in applications with high temperatures and high humidity environments.

Albarrie partners with acoustic panel manufacturers to design and produce nonwoven technical fabrics used to create acoustic products for sound absorption, diffusion, and vibration dampening. Once approved, we create a customizable but repeatable process to ensure your quality standards are met, make it simple to reorder on demand, and create a trusting partnership you can rely on to get your products to market.