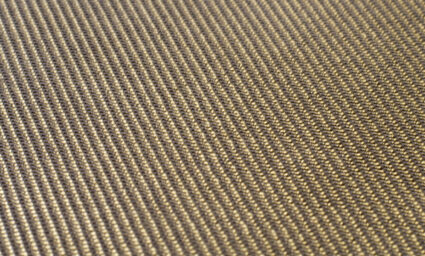

Polyphenylene Sulfide (PPS) is a high-performing fiber categorized as a thermoplastic polymer known as an engineering plastic. The fiber is highly resistant to chemicals such as acids, alkaline, organic solvents, and corrosion in high-temperature environments. PPS is also inherently flame and hydrolysis resistant. PPS is ideal for industrial air filtration where environmental conditions vary.

PPS has high tensile strength, contributing to good mechanical stability in harsh environments for wet and dry filtration applications. Since it can withstand chemicals and hydrolysis within a wide PH range, it also works in liquid filtration applications like belt filter presses.

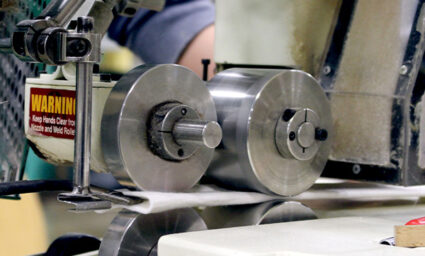

Albarrie relies on nonwoven PPS technical fabric’s performance for its Affinity industrial air filtration media, Cascade liquid filter media, and custom baghouse filter bags, including our exclusive Tandem and Meteor filter bags. Albarrie manufactures PPS in rolls from nine to 28 oz/yd² (330-950 g/m²), in thickness ranges between .039 and .118 in. (1-3 mm).