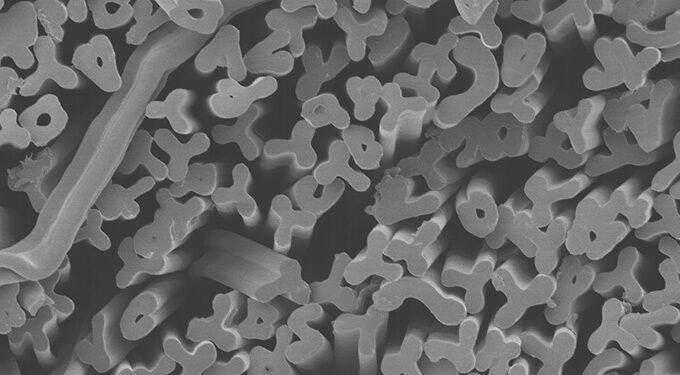

P84® Polyimide filter bags are excellent for air filtration in demanding industrial applications involving high temperatures, corrosion, and abrasion. This uniquely multilobular fiber offers a higher surface area for filtration, compared to other products in the market. With operating temperature of 460°F (237°C) and temperature surges of 500°F(260 °C), P84® Polyimide filter bags are non flammable.

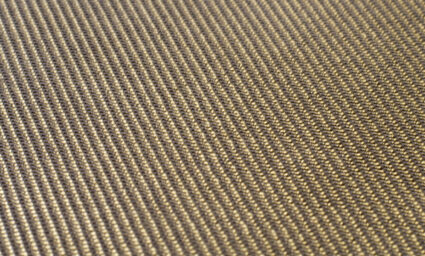

P84® polyimide technical textile is a high-performing industrial air filter media due to its high-temperature stability and enhanced filtration performance, resulting in cost savings in baghouse operations. Customers achieve enhanced filtration performance through improved dust capture on the surface and less blinding of the filter media. This results in less frequent bag changeouts, reducing maintenance and operating costs. In addition, the consistent filtration performance of P84® filter media helps ensure dust discharge over the filter’s life span. Peaks and surges can be managed effectively and stay within allowable limits.