In aluminum extrusion material handling, surface quality is often determined after the press—when profiles are still hot, soft, and especially vulnerable to dents, scratches, scuffs, and thermal-related defects. During lead-out, run-out, quenching, and transfer, even brief contact with rollers, beams, slats, or transfer arms can introduce surface issues that lead to scrap, rework, or downgraded product.

This is where high-temperature conveyor protection plays a critical role. Properly selected conveyor roller covers and slat & beam covers help reduce contact-related defects, protect surface-critical aluminum profiles, and improve overall extrusion line performance.

This guide explains the functional difference between conveyor roller covers and conveyor slat & beam covers, why both exist in extrusion plants, and how to select the right solution for each contact point.

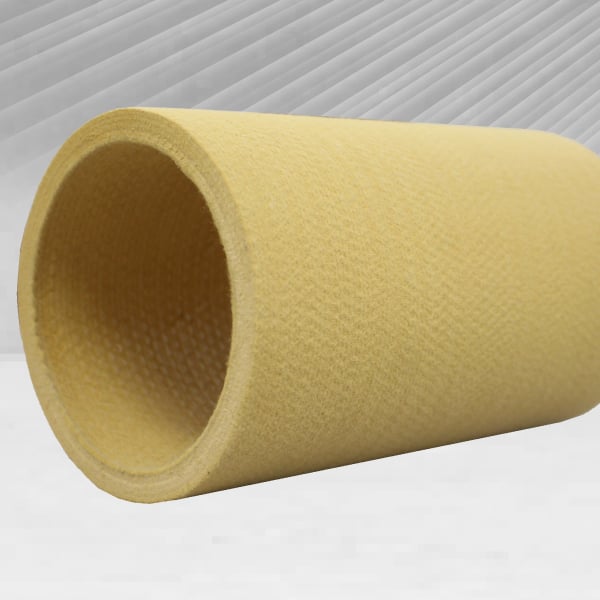

Conveyor roller covers (also referred to as roller sleeves) are protective coverings installed over individual rollers in aluminum extrusion conveyor systems. They provide a uniform, non-marking contact surface designed to reduce roller-induced dents, scratches, vibration-related marks, and finish defects as profiles move through roller tables.

They are commonly used in:

Conveyor slat covers and beam covers are pads, strips, or rigid boards applied to stationary or reciprocating contact points, such as slat conveyors, transfer arms, lift-over arms, and walking or standing beams. These components often replace graphite pads or boards to reduce surface marking and minimize dust-related housekeeping and maintenance concerns.

They are commonly used in:

Roller tables create rolling contact, where the roller rotates beneath the aluminum profile. In these zones, roller covers are designed to:

In short, if it rotates you use roller covers.

Slats, beams, and arms create sliding contact (profile moves against a surface) or resting contact (profile remains stationary). These wear modes behave very differently than rolling contact, which is why slat and beam covers are engineered as a separate category.

So, if the profile slides or rests you use slat & beam covers.

Extrusion lines are not exclusively roller-based or beam-based. A single line may include roller tables, walking beams, slat conveyors, and multiple transfer points—each with different motion, pressure, and temperature conditions.

As a result, aluminum extrusion wear protection is typically zoned by equipment type and thermal exposure, using different cover solutions optimized for each area rather than a one-size-fits-all approach.

Roller covers are optimized for continuous rolling, short-term contact where surface finish, vibration control, and temperature resistance are critical.

Key benefits

Material options

Roller covers can be manufactured in a range of engineered nonwovens, including blends using:

Slat and beam covers are designed for sliding or resting contact on stationary handling surfaces, managing friction based wear, drag, and dwell that can affect architectural finishes.

Key benefits

Material options

Slat and beam covers can be manufactured in a range of engineered nonwoven and board‑style materials, including constructions using:

Step 1: Identify the wear mechanism

Step 2: Match pad hardness to motion

Step 3: Confirm temperature and environment

Material selection should account for:

Many extrusion lines stage materials by temperature zone as profiles cool downstream.

Step 4: Focus on fit and interface

Proper fit is critical. Poorly fitted covers can introduce edges, wrinkles, or pressure points that show up as visible surface defects—particularly on architectural or anodized profiles.

Graphite pads and boards can contribute to surface marking and require additional housekeeping due to dust generation. Engineered nonwoven slat and beam covers are often used as an alternative in these applications.

Roller-induced dents and scratches

Bare or worn rollers can damage hot, soft aluminum profiles. Roller covers provide a protective interface to reduce these defects.

Noise and vibration in roller conveyance

Nonwoven roller covers can help dampen vibration and reduce noise associated with roller tables, contributing to smoother material flow.

When properly selected and applied, conveyor roller covers and slat & beam covers are complementary solutions, not competing ones. Understanding contact type, motion, temperature, and surface requirements allows extrusion plants to protect product quality, reduce scrap, and maintain consistent downstream performance.