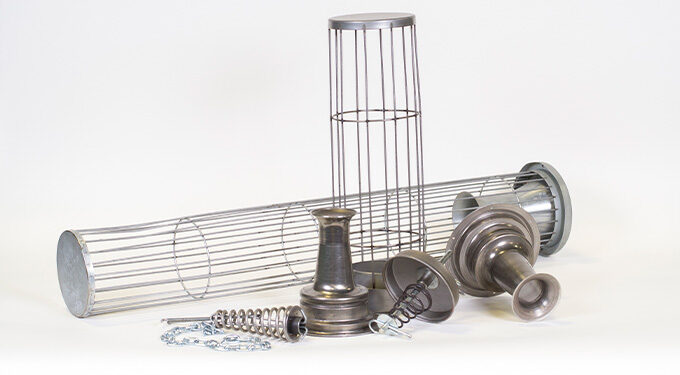

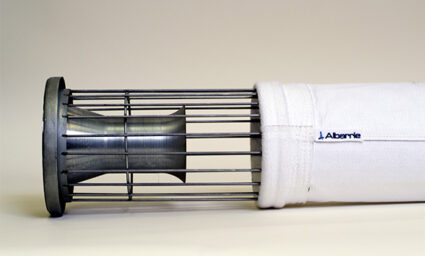

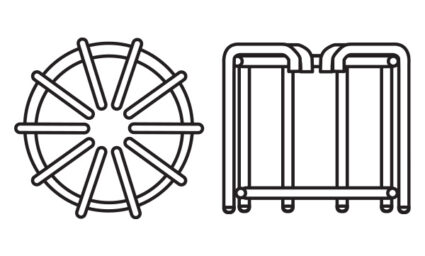

Cages and Venturis work together to maximize airflow through the baghouse filter media inside pulse-jet baghouses. While metal cages provide the needed structural support, venturis create negative pressure at the top of the bag, pulling additional air down into the filter elements during pulsing. The force provides a better air pulsing action and cleaning cycle. Generally, the longer the filter bag, the more critical it is to have a venturi in place. Without either of these essential parts, filtration is inefficient, and you’re at risk for emissions.

Cages must have the proper design structure to fit the baghouse and filter media properly. Most baghouses only need a one-piece cage; however, extra-long bags may require a two-piece cage design.

Two things determine the cage and venturi design: the baghouse design and filter media.

Baghouse Design & Cage Construction

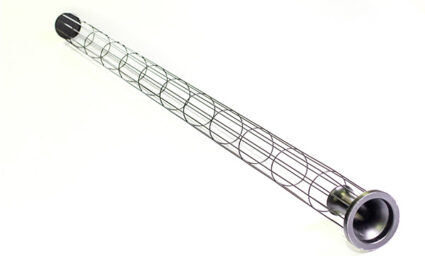

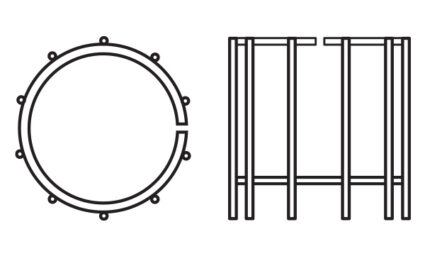

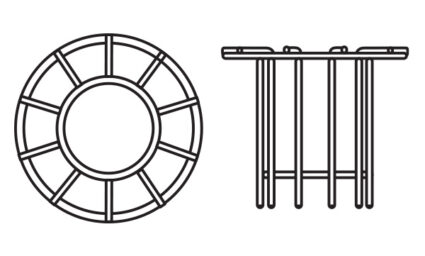

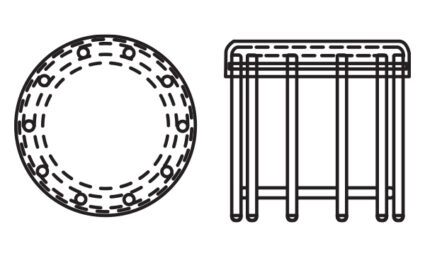

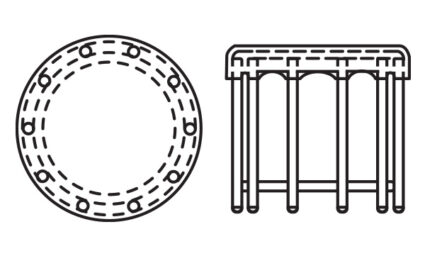

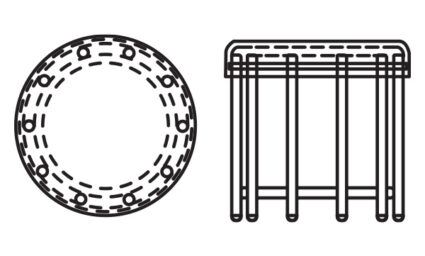

- Cage Top Design – top-loaded baghouses typically have a cage top with a rolled flange design, while bottom-loaded baghouses usually have a cage top with a split ring design. Other designs included slotted, roll band, all wire, or collar-venturi.

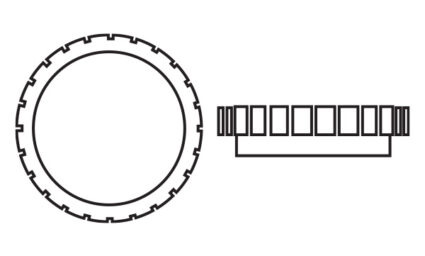

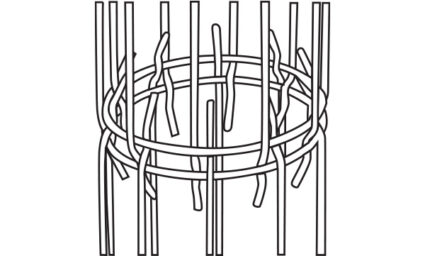

- Cage Bottom Design – Cages with a welded Bottom design have individual wires welded to them, while in crimped base design, the wires are crimped over the Bottom of the pan. Bottom cage designs can also include hemmed cups or wire formed.

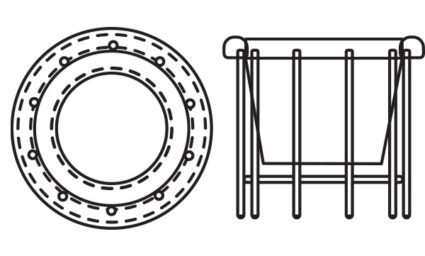

- Baghouses with 150 in. and 300 in. filter bags require two-piece cage designs. Two-piece cages have connectors in the center, which can be a finger connection, slide lock, or twist lock™.