Eliminate time-consuming hand-eye inspections in your baghouse. Albarrie’s leak detection kit uses a specifically formulated fluorescent powder and ultraviolet black light to quickly and efficiently detect leaks in fabric bags, seams, and welds. Our leak detection kits cut up to 90% of the leak detection time* during inspections, eliminating time-consuming hand-eye inspections. Our kits include the powder, a UV lamp, and safety goggles.

The Albarrie leak detection powder is easy to use and non-toxic. The powders work for wire cages in pulse-jet baghouses, shakers, reverse air, and cartridge-type dust collectors. The test confirms which filter bags have holes and identifies air leaks inside the baghouse compartment and filter equipment, eliminating unnecessary bag changes and downtime. The test can be performed by an in-house technician familiar with baghouse operations or the Albarrie service team.

Different Colors For Different Dust Types: Albarrie offers several colors of leak detection powder, suitable for various applications, depending on the dust’s chemistry. The goal of leak detection powder is to provide a quick visual of air leak locations. Once the dust settles onto the baghouse filter bags or baghouse equipment, the areas needing service are visible under the UV lamp. We recommend using contrasting colors to the process dust or other leak detection powders if you complete a second pass.

Our leak detection powder is available in five colors:

- Aurora Pink – suitable for all industries

- Blaze Orange – all industries except those where iron oxide is present

- Saturn Yellow – all industries except cement, lime, asphalt, utility, and cogeneration plants where sulfur is present in the dust

- Signal Green – aluminum, cement, and utility industries; good contrasting color for pink and orange

- Violet and other colors are good for plants that test multiple times yearly, allowing easy distinction between tests.

UV Lamps

Leak detection is impossible without the help of a UV lamp. Albarrie’s UV lamps are designed to quickly help maintenance personnel easily find leaks in any dust collection unit. We offer a full range of UV lamps, from inexpensive compact handheld UV lamps to more technically advanced ones. Our lamps have special orange safety glasses to prevent eye damage from UV light exposure.

Injecting Leak Detection Powders Into Baghouse

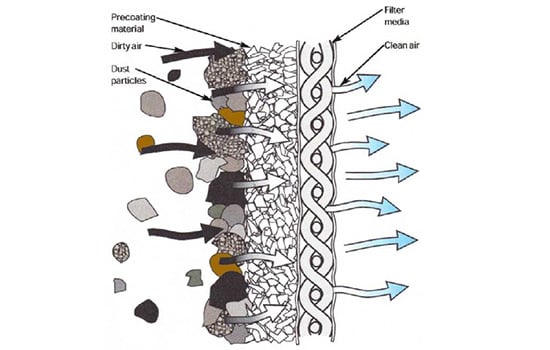

Inject the powder into an inlet port in the baghouse’s dirty air stream on the negative side of the fan. Do not put the powder into the hopper. After injection, the fan should run for at least 45 seconds but no longer than one minute. Holes or leaks are exposed by the powder’s fluoresces under a UV lamp. Once repairs are completed, inject a second powder color to mark any missed areas inside the baghouse.

Leak Detection Powder Calculation

Albarrie recommends using one pound (1 lb) of leak detection powder for 1,000 square feet or 0.5 kg per 100 square meters of filter cloth.

Available Sizes:

- 5 lbs pail (4/case)

- 10 lbs pail

- 25 lbs pail

- 150 lbs drum

- 300 lbs drum

Specifications:

| Average Particle Size |

3 microns (other micron sizes are available) |

|

| Color |

Pink, Orange, Yellow, Green, Violet |

|

| Refractive Index |

1.64 |

|

| Specific Gravity |

1.97 |

|

| Operating Temperature |

660°F (350°C) |

|