At Albarrie, we understand the value of keeping industrial baghouse systems running efficiently and cost-effectively. Albarrie recently undertook a large-scale replacement and servicing of 58,000 filter bags for one of our customers in the United States, demonstrating how regular maintenance not only restores performance but also extends the life of filtration equipment—even under demanding operational conditions

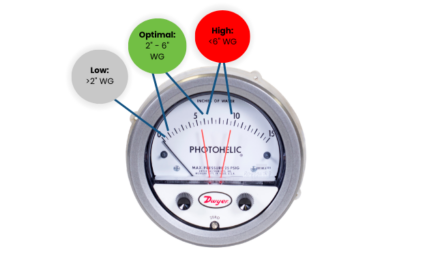

Baghouse systems play a vital role in high-temperature industrial processes, and consistent upkeep is needed to maintain their peak performance. Dust particulate buildup raises system resistance over time, leading to increased energy consumption and reduced efficiency. Through routine cleaning and maintenance, we help bring differential pressure readings down to optimal levels, which reduces strain on system fans and lowers energy costs.

During this on-site job, we brought heavily dust loaded filter bags back to life with Albarrie’s High Efficiency Cleaning (HEC). In addition to replacing some bags and cleaning the rest, the result was a significant reduction in Differential Pressure (DP) across the entire baghouse system. These improvements lead to immediate energy savings and improved airflow translating into cost savings.

In one example, filter bags that had become heavily loaded were restored through professional cleaning and replacing leading to a substantial reduction in static pressure across the system. These improvements translate into immediate energy savings and improved airflow.

The filter bags we service are often crafted for high-performance environments, such as the cylindrical 350-inch-long bags made from heat-resistant PPS with membrane coatings for chemically aggressive, high-heat applications. How often the bags need maintenance depends on a plant’s operating conditions, such as production load or unexpected system upsets, with cleanings typically performed either annually or bi-annually.

Our process also enables us to inspect and replace damaged or leaking bags before issues escalate. This proactive approach ensures filtration efficiency, minimizes dust re-entrainment, and reduces costly downtime.

Albarrie maintenance crews faced challenges when entering the worksite, from needing to work in a confined space and enduring high temperatures to operating under strict timelines. The service team had to bear temperatures as high as 140°F;even with cooling equipment present.We ensure our team is fully prepared to meet the demanding conditions of each job. Albarrie’s highly trained service professionals possess the expertise and the necessary certifications to work effectively, safely and efficiently in high-risk, complex industrial environments. They can complete large-scale projects within tight schedules—all while minimizing disruption to plant operations.

For this large-scale project, Albarrie’s experienced lead baghouse specialist successfully guided our expert team, coordinating all aspects of the job with precision and efficiency for the service team. Albarrie’s skilled service crew carefully planned each phase of the project to ensure a seamless execution.By taking only 10% of the filter compartments offline at a time, they successfully maintained continuous facility operations while servicing the remaining compartments. Through strong teamwork, organization, clear communication, and a step-by-step approach, Albarrie’s experienced team made sure every part of the project was completed safely, efficiently, and with the highest level of care. This focus on good planning and teamwork is what helps us take on big, challenging jobs without causing major disruptions.

Routine inspections and cleaning have a profound impact on the performance and longevity of baghouse systems. Clients routinely report extended filter bag life, often exceeding initial expectations by several years when consistent maintenance is performed. Improvements in differential pressure, reduced wear on system components, and increased reliability make regular servicing a worthwhile investment.

At Albarrie, baghouse maintenance goes beyond simply cleaning filter bags. Our approach is designed to restore performance, prevent expensive system failures, and ensure compliance with environmental standards. By combining high-performance materials, technical expertise, and an experienced team, we help industrial operators optimize their filtration systems for enhanced reliability, efficiency, and long-term cost savings.