Baghouses—also known as dust collectors—are essential to industrial dust collection systems. Widely used in industries such as power generation, cement, mining, and food processing, these systems play a key role in meeting EPA air quality standards and maintaining a clean, safe work environment.

At Albarrie, we help clients choose the right filter bags to optimize filtration efficiency, minimize maintenance, and extend equipment life.

Filter bags are generally made from two types of fabrics woven and non-woven each offering unique benefits depending on the application:

Albarrie’s needle-punched, non-woven filter bags are engineered for strength, reliability, and fine dust capture. With customizable media options, they provide versatility for a wide range of baghouse systems and filtration needs.

To ensure the best performance, consider the following factors when choosing your filter fabric:

The air-to-cloth ratio (also known as filtration velocity). A proper ratio ensures even airflow across the bag surface, minimizing pressure drop and energy usage while extending bag life.

The type of baghouse system pulse jet, shaker, or reverse air influences your filter bag selection:

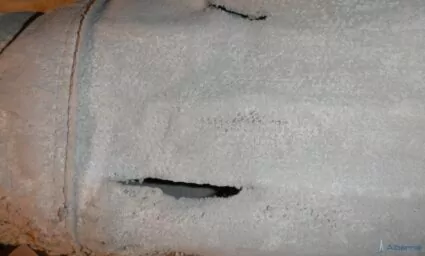

Filter bag lifespans can typically range from 2 to 8 years, depending on environmental conditions, media quality, and maintenance practices. Albarrie recommends regular inspections to monitor for wear and performance loss.

A proactive maintenance schedule—including leak testing, bag cleaning, and timely replacement—can help reduce unplanned downtime and extend the overall life of your system. Albarrie HEC service technicians can assist in maintaining production efficiency resulting in cost savings for your premises.

Selecting the right filter fabric means balancing your budget, performance needs, and operating environment.

Proper sizing is just as important as fabric selection:

Oversize or undersize bags will cause issues through out the process resulting in premature wear and tear leading to failure.

Albarrie’s vast experience in filter bag manufacturing and maintenance brings proper knowledge in how to properly size filter bags.

Choosing the right filter bag involves more than just matching dimensions. It requires a clear understanding of your dust characteristics, system type, and environmental demands. By selecting the appropriate Albarrie filter fabric and committing to a regular maintenance program, you’ll ensure cleaner emissions, regulatory compliance, and more efficient, cost-effective operations.

For tailored recommendations or to explore Albarrie’s range of high-performance filter media, contact our team today.