Governing regulations ensure the safety of workers, the environment, and general public in the oil and gas industry. Albarrie helps companies comply with these regulations, using our patented and reliable secondary oil containment systems and high performance industrial air filtration.

The oil and gas industry is a vital part of the global economy, and it is crucial to have reliable and safe systems in place to protect workers, the environment, and the public. Numerous operations within the oil and gas industry are addressed by regulations, and Albarrie helps with two: secondary oil containment systems and industrial air filtration.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of secondary containment and air pollution control products.

Improve efficiencies and lower maintenance costs with Albarrie’s line of products for secondary containment and air filtration.

Our products are designed to meet North American requirements for secondary containment and air pollution control.

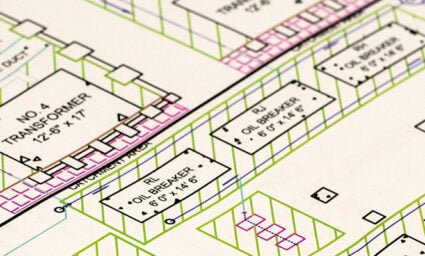

Producing oil and gas can be a hazardous operation. As a result, producers within the industry must adhere to various regulations that help protect their workers, the environment, and the general public. One such area of regulation is with transformer secondary oil containment systems.

Albarrie’s secondary oil containment systems help prevent transformer oil from leaking into the environment, minimizing the damage caused by an accidental release. Our smart fabric technology and containment designs – SorbNSeal™, EsterWeb, and Oil Blocker Plus – lead the way in secondary containment products on the market today. We have the experience and expertise to help keep operations safe, comply with regulations, and save money.

Another important area of regulation for the oil and gas industry is industrial air filtration. Air pollution can be a significant hazard in any industrial setting, and it is crucial to have a system that cleans the air before it exits the facility. Albarrie offers a wide range of industrial air filtration solutions, from high-efficiency cleanings to custom baghouse filter bags fitted specifically for oil and gas operations.

Oil spills are a major environmental concern in the oil and gas industry. Not only can they cause extensive damage to ecosystems, but they can also be very costly to clean up. Oil spills don’t only come from the oil or gas that’s produced but also from the transformers that power operations. One way to help prevent transformer oil from spilling into the environment is to install a secondary oil containment system. Albarrie’s secondary oil containment systems for transformers are designed to be virtually maintenance-free. Our systems use patented smart fabric technology to immobilize oils on contact while allowing water to pass through the system, preventing water from remaining inside the containment. Unlike concrete containments, the system remains ready for oil spills during significant rainfall and keeps personnel from having to drain the system.

Albarrie’s secondary oil containment systems help minimize an oil spill’s impact, making it easier to clean up. They also help reduce the fire risk with a layer of fire quenching stone. By installing Albarrie’s secondary containment system around transformers, oil and gas companies can help protect the environment, reduce the potential for costly cleanups, and save money and time with a maintenance-free design.

Baghouse filters are an essential component of the oil and gas industry. They play a crucial role in controlling emissions from processing plants and equipment. They also help to protect workers and the environment from harmful contaminants.

When operating a baghouse, producers must consider several factors: The type of gas coming through the system, operating temperatures, humidity, and dust loading. All of these factors will determine the type of fabric best suited for a custom baghouse filter. Albarrie’s custom baghouse filter bags are made to fit your system with nonwoven fabrics designed to capture dust particles in high-temperature operations. Albarrie’s specialty fabrics, Tandem and Meteor are designed to handle chemically-invasive environments at high temperatures. Our experts will help you pick a fabric best suited for your dust loads, taking into account the chemical make-up of your process.

Producers must clean baghouse filters regularly to maintain efficiency. Although pulse-jet cleaning systems can clean the filters daily, they cannot give the bags a deeper clean. Keeping the bags clean is vital, so they do not become clogged and lose effectiveness. Albarrie offers baghouse maintenance services to help you resolve baghouse problems and keep filters clean with our High-Efficiency Cleaning.

If you are operating a baghouse filter for the oil and gas industry, it is important to know how to maintain and operate it properly. Failure to do so could result in decreased efficiency or even damage the equipment.