Dust control systems capture and contain dust particles created during chemical and pharmaceutical manufacturing processes, and reduce environmental risk caused by catastrophic oil spills from transformers or oil-filled equipment on your property.

As industrial air filtration experts, Albarrie helps chemical and pharmaceutical manufacturers to comply with health, safety, and environmental regulations around toxic dust, emissions, and hydrocarbons. It’s what we’ve done for over 40 years. Albarrie makes recommendations on the right kind of nonwoven filter media/fiber to effectively trap fine dust, particulate and other harmful elements. Our secondary oil containment smart solutions solve challenges around oil-filled equipment like transformers, leaking into the environment and navigable waters.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie’s line of products for air filtration and secondary containment.

Our products are designed to meet North American requirements for secondary containment and air pollution control.

The chemical and pharmaceutical industries are two critical industries today. They provide us with the medicines we need to live and help us make things like food, fuel, and cosmetics. But their manufacturing processes are hazardous, producing moist, sticky, oily, or static-producing fine dust with a wide variety of toxicity levels. If the dust gets into the air, they carry significant health and safety risks in the workplace and local environment. Chemicals and pharmaceutical powders present challenges in mitigating their potential for fire, dust explosions, and harming employees. Controlling dust exposure in the workplace is a priority to avoid regulatory fines and long-term health damage to personnel. Each process in these industries typically requires dust collectors or baghouses to filter fine, toxic particles from the air.

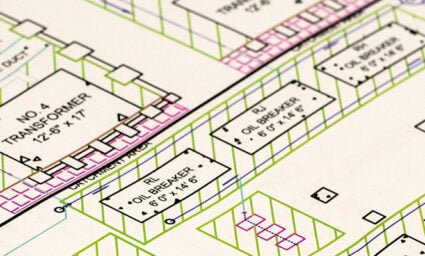

The chemical and pharmaceutical industries also require electrical substation transformers to power operations. Transformers come with significant environmental risks, especially around environmentally sensitive areas. They are prone to chronic leaks and catastrophic spills, leading to environmental damage and regulatory fines. By regulation, transformers require a SPCC plan for to mitigate spills around oil-filled equipment. Traditional containment systems such as concrete are labour intensive, maintenance heavy, and high-cost solutions, that cut into operating budgets.

Without the correct filter bags and support, the dust collector or baghouses in chemical and pharmaceutical processing facilities could leak or, even worse, explode from the toxic, flammable particulate. The high toxicity of the chemicals also gets into the stream, causing abrasion and low service life from filter failure. Albarrie’s exclusive Tandem and Meteor baghouse filter bags are ideal for chemical and pharmaceutical applications to help mitigate these issues. Other suitable choices for these industries include PTFE, polypropylene, P84® polyimide, meta-aramid, and fiberglass filter bags, along with various treatments and finishes to enhance filtration processes. Selections for these processes depend on operating temperatures, environmental conditions, and the particulate in the air stream. Our team will consult with you to design the ideal air filter media for the application. We also offer cartridge and pleated filters for dust collectors, baghouse accessories, and expert services to meet operational, budgetary, and environmental demands.

Albarrie designed its transformer secondary oil containment systems to reduce the environmental risk caused by catastrophic oil leaks and spills from transformers or other oil-filled equipment. Our systems protect you from heavy regulatory fines, costly clean-ups. We developed our patented oil-reactive, self-sealing smart fabric to keep oil containment systems virtually maintenance-free, delivering significant cost savings on installation and operation.