Albarrie’s products help you avoid environmental damage, regulatory fines, and operational cost creep by creating efficiencies that save your most valuable resources – money, time, and the environment.

Operation and production managers rely on their equipment, processes, and personnel to ensure their plant operates smoothly. But nothing always runs smoothly. Eventually, equipment breaks down, leading to cumbersome maintenance issues, and cost creep. The last things producers want to worry about are environmental compliances issues, safe and healthy work environments, and cost overruns.

Albarrie manufactures high-quality filter bags, and oil spill containment solutions, needed and relied on by the mining and metal industry. Our secondary oil containment solutions use a smart self-sealing technology that traps and locks, leaked oil on contact, around transformer, substations and large oil filled equipment or generators. Our customized industrial filter bags are made with unique fiber properties that ensure dust and emissions are within regulatory levels, while our heavy weight geotextiles are used for weak soil reinforcement, pond protection, erosion and more.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie’s line of products for air filtration and secondary containment.

Our products are designed to meet North American requirements for secondary containment and air pollution control.

The mining and metals industry generates high levels of dust from crushing, screening, and material handling when filling silos and bins or loading materials for transport. Dust particles could easily exceed regulatory limits which are set to ensure workers, or the surrounding communities aren’t exposed to abrasive, and harmful dust. Mitigating the risk from large volumes of fine, invisible dust is a major priority for the industry. This has led to producers using dust collectors or baghouses to capture that dust.

Secondary processes, such as smelting and alloying, demand high temperatures to melt raw materials for extracting or mixing. Baghouses with a fabric filter are best suited to remove harmful particulates like metal oxides and zinc from the flue stream.

Drying kilns is another process that produces off gases with large amount of particulate matter. The dust and particulate matter produced by the mining and metals industries rapidly wear out baghouse filter bags, leading to baghouse leaks and frequent maintenance. Without effective dust control – equipment, process, employees, and the environment may be at risk, and production could be halted.

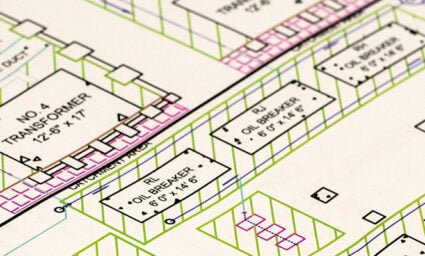

Mining operations need power for their processes, often requiring transformer substations and other oil-filled equipment on their property. Transformers are prone to leaks and major spills, which means they must have a preventative solution, such as secondary oil containment systems to avoid high fines and costly cleanups.

Although the mining and metals industries use dust collectors and baghouses to operate effectively, it’s actually the air filter media (or fabric) that does the work. Choosing the best fabric for the application helps reduce the risk of high dust levels, emissions, and dust explosions. However, the fabric must also resist the chemicals or other compounds within the flue gas stream, high operating temperatures, and abrasion.

Albarrie’s exclusive Tandem™ and Meteor™ baghouse filter bags are suitable for high-temperature applications in the mining and metals industries to help with problems such as abrasion and low service life, which are caused by toxic chemicals getting into the gas stream. Other suitable choices include PTFE, polypropylene, and P84® polyimide filter bags for high-temperature applications. Polyester or acrylic are better suited for baghouse applications with low-temperature processes. Albarrie also provides a full spectrum of cartridge and pleated filters, cleaning and maintenance services, and baghouse accessories. Our experts can assess the situation and recommend solutions based on your specifications to deliver the best performance.

Traditional containment solutions, such as concrete baths, are labor-intensive, maintenance-heavy, and high-cost solutions that cut into operating budgets. Albarrie’s secondary oil containment solutions for transformers at mines and metal processing facilities include our patented oil-reactive, self-sealing smart fabric

to keep oil containment systems virtually maintenance-free. Our secondary oil containment systems are cost-effective over traditional solutions, decreasing maintenance costs and minimizing onsite personnel. This leads to a reduction in environmental risk, regulatory fines, and operational costs incurred by the equipment owner.