Renewable energy can help us move towards a greener future, but it also comes with environmental risks. Substation transformers and dust collectors are important components of renewable energy infrastructure; however, they can become environmental liabilities when improperly maintained.

Transformers are filled with thousands of liters of oil, which leak or cause major spills, as is the case when this equipment fails. Although many organizations fill transformers with environmentally-friendly oil, this oil produces a sheen, which is harmful to the environment. Secondary containment for spill prevention is essential to keep all oils from our rivers, lakes, and oceans.

Dust collectors filter out particulate from processes and operations and keep harmful emissions from going into the atmosphere. However, when baghouses are improperly maintained, air filter media can fail, discharging harmful dust particulate and chemicals into the air we breathe. Albarrie’s secondary containment and baghouse solutions help protect the environment and shield producers from these risks.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie line of products for filtration, and secondary containment

Albarrie is a North American Technical fabrics manufacturer, our products are made in North America and are designed to meet North American requirements.

Environmental risks must be considered when planning any renewable energy project. The potential for transformer oil spills is especially concerning, as even a small spill can have devastating environmental consequences. Therefore, it is essential to minimize these risks by choosing solutions that prevent spills from leaking into our land and waters by installing an effective secondary oil spill containment system.

Similarly, ensuring that the baghouse or dust collector systems or baghouses are functioning correctly and not emitting harmful air emissions is essential. If these systems are not working correctly, they will cause severe health and environmental problems in our communities. Employing the right filter bag and performing routine check-ups is vital to ensure that they operate safely and effectively.

Taking these precautions can help reduce the environmental risks associated with renewable energy facilities.

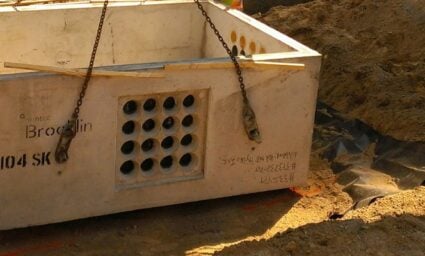

Renewable energy facilities often come with large-size oil-filled operational equipment such as transformers and switchgear. Unfortunately, this equipment is prone to leaks and failures, potentially leading to large oil spills if organizations don’t implement proper secondary containment or spill prevention measures. With hundreds of installations in North America, Albarrie has been a leading innovator of secondary oil containments for transformer substations, in solar and wind farms, nuclear power plants, hydroelectric plants, biomass, and more. Our experience has made us a leader in the field, and we continue to develop new and innovative ways to protect organizations and the environment from transformer oil spills.

Transformer failure can significantly impact the overall operation of renewable energy. That’s why it’s essential to have a reliable secondary oil containment system. Traditional “do nothing” approaches and concrete systems are unreliable and high maintenance, requiring staff, oil water separators, and pump and -treat systems to remove water after a rainfall event. If staff or pumps fail, the containment doesn’t have enough capacity to capture catastrophic oil spills, posing a threat to the environment. Albarrie’s containment design uses oil-immobilizing smart fabric technology that allows rainwater to pass through but stops and immobilizes oil on contact, preventing it from escaping the containment area. Our systems – SorbNSeal™, EsterWeb, and Oil Blocker Plus – are easy to install and virtually maintenance-free, saving developers and owners money by reducing build costs, maintenance, and clean-up costs, protecting the company from costly fines and potentially damaging reputation.

Albarrie’s transformer secondary oil containment systems are an eco-friendly, flexible, and customizable solution for any greenfield or brownfield project. We continuously test our products to ensure their effectiveness, maximum functionality, and customer satisfaction with every containment system we design.

Baghouses are a critical part of the renewable energy industry. The primary purpose of a baghouse is to remove dust and particulates from the air. This is important for two reasons. First, it keeps the air clean and safe for workers and equipment. Second, it prevents dust from entering the environment and creating pollution.

There are many different baghouse filter bags, each designed for a specific purpose. Producers must consider several factors to optimize baghouse operations – operating temperatures, baghouse humidity levels, chemicals in the gas stream, and dust loads. The type of baghouse filter bag depends on the factors previously mentioned. For example, a baghouse filter used in a biomass plant would be different than one used in a coal-fired power plant.

Albarrie’s custom baghouse filter bags capture the particulates before they exit the system in high-temperature operations. Our exclusive Tandem and Meteor filter bags have proven to create highly efficient filtration, providing a longer bag life. We also offer other fabrics such as PPS, Meta–Aramid, P84 Polyimide, Fiberglass, Polyester, Acrylic, and more. We offer a full range of baghouse accessories and preventative maintenance products to keep operations running smoothly. Customers use Albarrie’s filtration experts to help maintain baghouses and troubleshoot issues.

Albarrie’s experts can help you design a filter bag that will save you money in the long run. When the filter media and fit are correctly matched to the process and system, differential pressures stay steady, saving you money by consuming less energy.