Albarrie works with engineers and construction companies to create efficiencies that save some of the most valuable resources – time, money, and the environment. From oil spill containment measures, to air filtration and heavy-weight geotextiles, Albarrie manufactures nonwoven technical fabrics to create efficiencies for numerous construction & engineering projects.

Our innovative technical fabrics, products, and services keep the construction and engineering industry operating within compliance of health, safety, and environmental regulations. Our baghouse and secondary containment solutions optimize efficiencies and equipment operations to save time and money. Albarrie is committed to helping engineers and contractors win new projects by providing them with the stamped final designs, as-built drawings, and other resources they need to win projects for substation designs.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie’s line of products for air filtration and secondary containment.

Our products are designed to meet North American requirements for secondary containment and air pollution control.

CO2 emissions have been linked to climate change, global warming, and human health problems. The North American construction sector is a significant contributor to greenhouse gas emissions, accounting for 40% of Global greenhouse gas emissions (WBCSD 2018). However, emissions aren’t the only pollutants causing problems. Oil leaks are also a substantial contributor to environmental pollution and damage. According to the71percent.org, “a single gallon of oil can contaminate as much as one million gallons of water. Spilling a pint of oil in a wetland or lake could cover the surface area of an acre of water.”

These environmental issues have forced North American governments to enact tighter environmental controls and regulations as they try to improve global ecological outcomes. Complying with environmental standards is a priority for many sub-industries like asphalt, aggregate, cement, gypsum, and lime manufacturing. Many of these producers also have oil-filled equipment like transformers and storage tanks to power operations. The equipment is prone to chronic oil leaks and catastrophic spills into the soil and navigable waters, causing damage to ecological life. The industry must comply with secondary containment regulations for oil-filled equipment.

Although the environment is a concern, government shutdowns or fines for non-compliance can lead to production losses and less cash to drive the business.

A critical piece of equipment for producers in the construction industry are dust collectors and baghouses. They are high-maintenance items with many consumable parts that need to be continuously replaced. Manufacturing operations in this industry produce toxic dust particulate in the gas flue stream from making building materials for roadways and facilities.

Nonwoven baghouse filter bags are essential for separating the pollutants from the gas stream. Filter bags must be made from industrial fabrics capable of withstanding abrasive, toxic dust in high-temperature environments. Albarrie’s baghouse filter bags and services mitigate harmful particulates, thermal loading, and bag blinding issues while creating efficiencies in the operating equipment. We offer a variety of fibers, including PTFE, polypropylene, polyphenylene sulfide (PPS), polyimide P84®, meta-aramid, and fiberglass for high-temperature applications. Our acrylic or polyester fibers work well for lower temperature applications. Albarrie’s exclusive Meteor and Tandem bags

are ideal for harsh chemical conditions. We also offer cartridge

and pleated filters for dust collectors, baghouse accessories, and expert services to meet operational, budgetary, and environmental demands.

Fabric selections depend on operating temperatures, environmental conditions (humidity levels), and particulate in the air stream. Our team will consult you to design the ideal air filter media for the application.

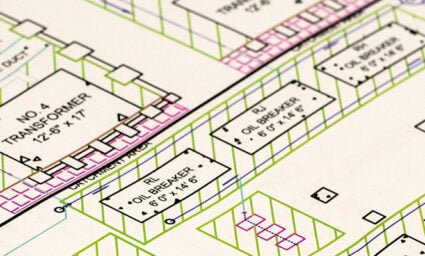

Albarrie’s transformer secondary oil containment systems are designed to reduce environmental risk and ensure compliance with regulations

while protecting the facility and budgets from hazardous spills. Our patented oil-reactive, self-sealing, smart fabric is a proven technology used in thousands of containments in North America. It reacts with transformer oils, forming an impermeable barrier that prevents oil leaks while allowing water to drain, creating a maintenance-free containment.

Albarrie’s secondary containment systems are custom designed to site conditions and equipment specifications. Our engineering design services are used by contracting engineers and contractors to bid on and win new projects. Albarrie is certified with the Professional Engineers of Ontario (PEO) to provide secondary containment services that are within the practice of Professional Engineering in the Province of Ontario. We offer stamped drawings as part of our complete IFC package.

Nonwoven heavyweight geotextiles are heavy-duty, durable

technical fabrics used to reinforce weak soils and sand beds, provide stabilization of slopes, pond protection, filtration, and erosion control. The unique fiber orientation of these geotextiles makes them highly resistant to abrasion, puncture, and tearing. These attributes make our heavy-duty nonwoven geotextiles ideal in conditions where high strength, rigid support, and reinforcement are needed without dramatically affecting groundwater levels. Contractors rely on Albarrie’s capability to produce extra heavy textiles, slitting to customized lengths for easier handling in the field.