Albarrie works with food and beverage producers to ensure baghouses and dust collectors operate efficiently. Poorly functioning dust collection systems or baghouses can result in fines, penalties, and eventually facility shutdowns. Albarrie innovates industrial filtration products and oil spill containment systems that save money, reduce risk and meet government environmental regulations during food production.

Food and beverage manufacturers face increasingly rigid production regulations, leaving facility managers and operators with several challenges – inefficient air and dust pollution measures, dust combustion, onsite oil spills from large oil filled equipment, and high operational costs. Albarrie works with producers to solve these issues, comply with regulations, and save operational costs.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie’s line of products for air filtration and secondary containment.

Our products are designed to meet North American requirements for secondary containment and air pollution control.

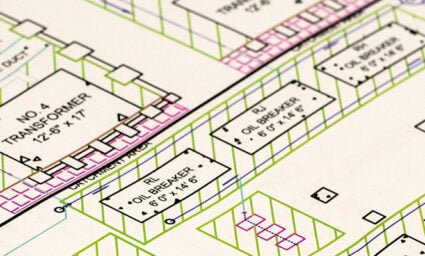

Poorly functioning dust collection systems or baghouses can result in fines, penalties, and even facility shutdowns. These systems rely on air filter media (baghouse filter bags, cartridges, or pleated filters) to filter toxic, oily, sticky dust particles from the air. When dust collectors and baghouses leak or fail, there is a significant increase in dust accumulation and eventually, respiratory illnesses due to poor air quality. Keeping operating costs and downtime to a minimum is critical to the bottom line. Albarrie works with food and beverage producers to ensure baghouses and dust collectors operate efficiently. Through regular maintenance and High-Efficiency Cleaning, we help preserve filter bag life. If manufacturers have a transformer on site, Albarrie’s secondary oil containment systems are maintenance-free, self-sealing, and trap leaked oil on contact, to avoid catastrophic oil spills. Our smart fabric technology saves your organization time, costly cleanups, and government fines.

Successful and efficient dust collection comes from operating at peak performance to maximize savings. This means longer filter life, steady differential pressures, and preventing combustible dust – a hidden danger in the food industry. Food particulate can be more prone to ignition than other types of dust. Common food dust hazards include cereal ingredients, spices, feed, raw grain, agricultural products, eggshell dust, flour, corn starch, sugar, tea, and flavoring additives. Albarrie’s air filtration experts help determine the air filter media type that will work best for the application, addressing potential hazards in the process. Whether a PTFE or polypropylene baghouse filter bag, cartridge, or pleated filter is required, our technology team will advise on fiber choice, finishes, and treatments. Enhance baghouse performance with our complete line of baghouse accessories—baghouse seals, pre-coat and leak detection, cages, and parts. Our services team offers high-efficiency cleanings, preventative maintenance, and troubleshooting services.

It’s also no surprise that food and beverage facilities need reliable heavy-duty power transformers to facilitate production. When those transformers malfunction, the risk of secondary oil spillage increases, along with the risk of contamination and environmental damage. Albarrie engineers manufactures, supplies, and installs transformer secondary oil containment systems and oil spill containment systems using patented oil-reactive, self-sealing smart fabric technology – making them virtually maintenance-free. We offer several different containment designs customized by our in-house engineering team. Our containments save you money by reducing the need for ongoing maintenance or repairs, giving producers peace of mind knowing that the business is protected from the heavy fines and costly cleanups due to transformer spills.