Pulp and Paper manufacturers rely on Albarrie’s expertise for effective air filtration products and services, as well as maintenance free secondary containment around their transformers or large oil filled equipment.

From packaging products to tissue paper, magazines, books, copy paper, and more, there’s no doubt the world’s consumption of paper products is enormous. Albarrie is committed to helping manufacturers reduce environmental risk and maximize uptime. Paper is made from wood, which requires converting the raw material into pulp. Each process within the industry produces harsh environmental air contaminants, requiring air filtration and dust collection. We assist pulp and paper producers by improving filtration efficiencies that save time, money and help them meet environmental regulations.

Keep workers and the local community safe by keeping harmful particulates out of the environment.

With Albarrie’s line of air pollution and spill control products.

Improve efficiencies and lower maintenance costs with Albarrie line of products for filtration, conveyance, and secondary containment.

Our products are made in North America and are designed to meet North American requirements.

From packaging products to tissue paper, magazines, books, copy paper, and more, there’s no doubt the world’s consumption of paper products is enormous. The pulp, paper, and wood industries are heavy polluters. Paper is made from wood, which requires converting the raw material into pulp. Each process within the industry produces harsh environmental air contaminants, requiring air filtration and dust collection.

Dust collection in the pulp and paper industries comes in many different forms. So, whether it’s a baghouse, cartridge filter system, or cyclone, producers must carefully consider the type of air filtration best suited for the application – dust types, gasses in the flue stream, the potential for dust explosions, clogs, and leaks. All of which lead to more work, environmental hazards, and high operating costs.

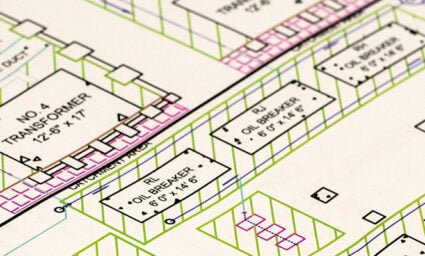

Air pollution isn’t the industry’s only environmental pollutant. They also have the potential for oil spills from on-site substation transformers used to power operations. Transformers tend to leak insulating oil, but they can also succumb to catastrophic failures leading to oil spills into the soil and nearby waterways. Regulations require asset owners to have a plan that reduces the risk of a transformer oil spill and prevents it from reaching navigable waters to protect public safety and the environment.

From abrasive wood dust to potent gases containing sulfur oxides (SOx), volatile organic compound (VOCs), and nitrogen oxides (NOx) – the pulp and paper industries require excellent dust collection and air filtration operations to mitigate risks around their employees’ and communities’ health and safety, not to mention fines or shutdowns from regulatory bodies.

Baghouses are the most effective type of air filtration system across many industries. They use nonwoven air filter media to separate the particulate and gasses from the air stream. Albarrie’s unique and exclusive baghouse filter bags, Tandem™ and Meteor™, are both excellent selections to deal with many gasses, by-products, and dust combustion risks from the pulp, paper, and wood industries. Meta-Aramid, fiberglass, PTFE, Polyphenylene, PPS, Polyimide, and fiberglass are all fibers that can withstand many harsh chemicals in high-temperature applications. For lower temperatures, acrylic and polyester are suitable.

Albarrie’s expertise help improve baghouse and dust collector operations to reduce overall operating costs. We provide technical expertise in baghouse filter bag design, cage support design, troubleshooting, preventative maintenance, and leak detection. We also offer various baghouse accessories such as seals, cages and venturis, cartridge and pleated filters, precoat and leak detection powders, timer boards, and replacement valves.

Stay protected from heavy fines and cleanup costs associated with transformer oil spills. Albarrie offers several different transformer secondary oil containment designs customized by our in-house engineering team. Traditional oil containment systems require heavy maintenance and monitoring, but Albarrie uses a patented oil-reactive, self-sealing smart fabric technology resulting in a virtually maintenance-free system. As a result, our containment products save money by reducing the need for ongoing maintenance or repairs and protecting the business from costly fines and cleanups.